English

-

-

Industries

- Dust-extraction crushing system

- Pulse dust-extraction grinding ssytem with ribbon mixer

- Ultra-micro crushing system with vacuum conveyor

- Coconut Powder

- Cocoa Powder-Horizontal Ribbon Mixer

- Medicine

- Rice Flour

- Sand-Plastic Powder

- V-Type Mixer for Metal Poweder

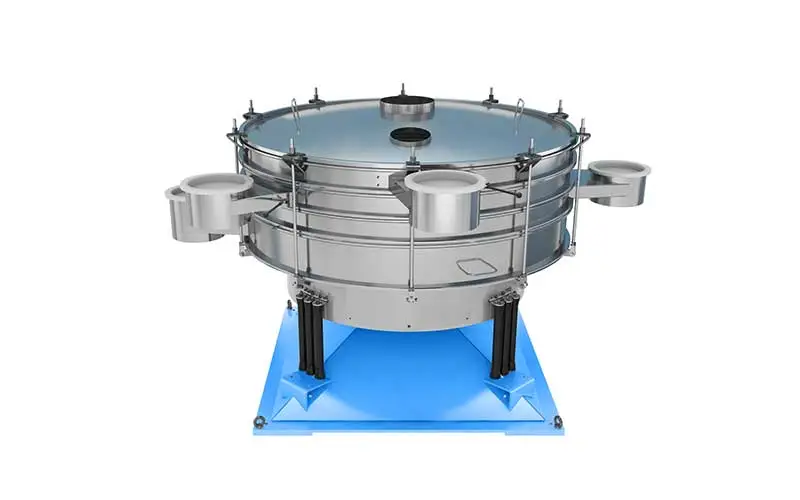

- Vibrating Rod

- Battery Material

- Seafood

- Silica Powder

- Starch

- Vitamins Material

- Metal Powder-Nickle Iron Alloy Material

EN

EN