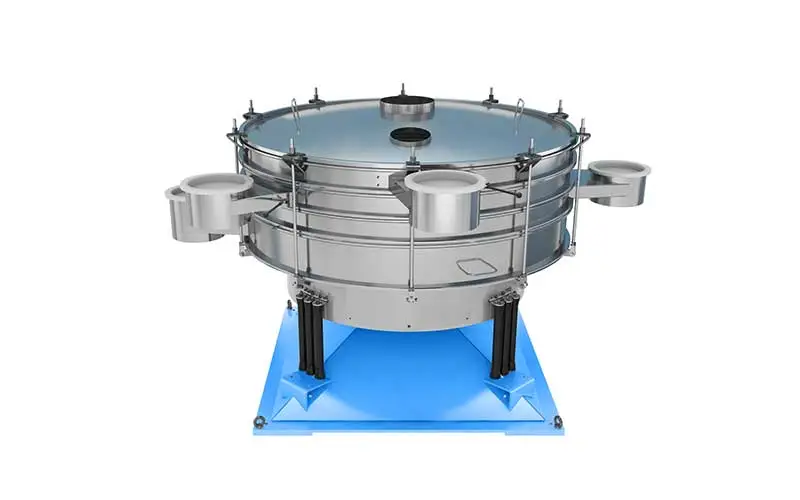

Tvtion has established itself as a premium supplier in the industrial machinery sector, specializing in manufacturing, marketing, and developing advanced blending and separation equipment for the global powders industry. Among its innovative product range, the square cone mixer stands out as a remarkable achievement in powder blending technology, offering superior mixing performance and operational efficiency.

Technical Superiority of Tvtion Square Cone Mixer

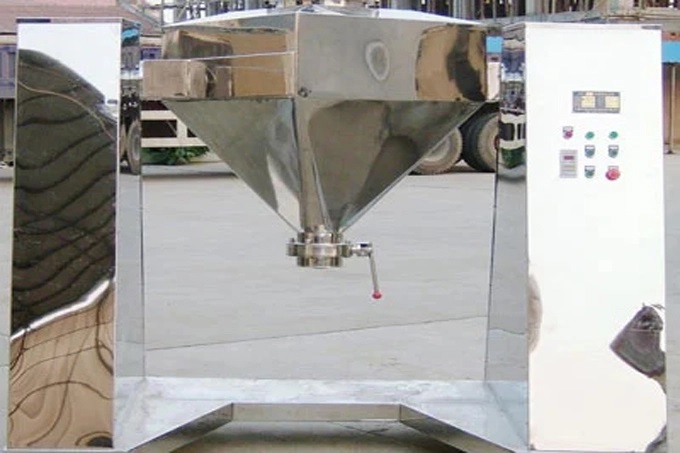

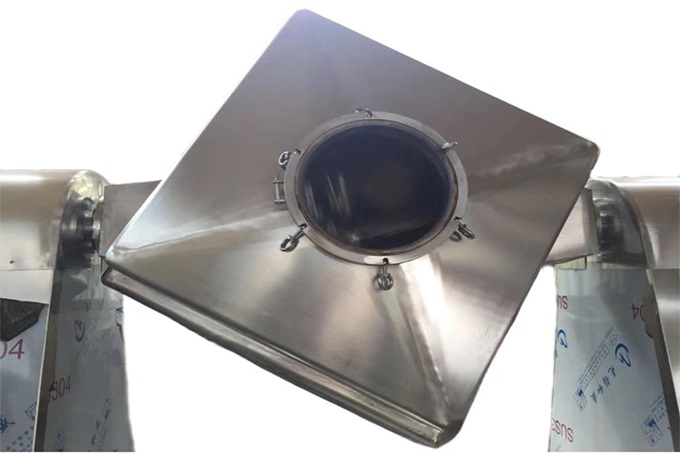

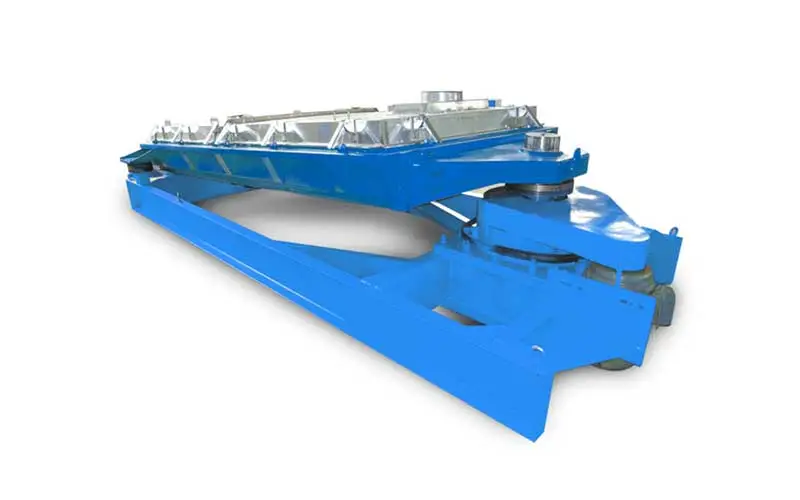

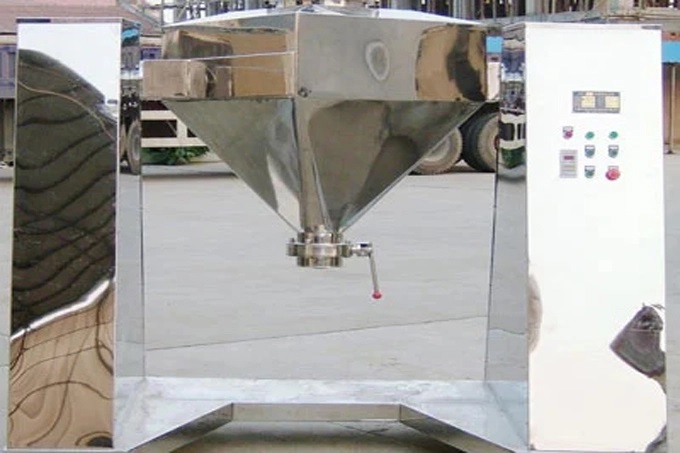

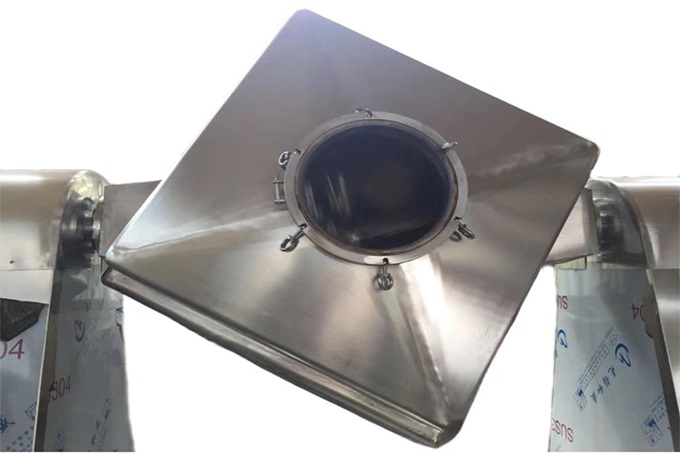

The square cone mixer represents Tvtion's engineering excellence in powder processing equipment. This innovative blender features a unique geometric design that combines a square cross-section with conical ends, creating a mixing action that ensures thorough blending of materials. The machine's principle of operation involves the gentle tumbling of powders through the main spindle of rotation, which prevents segregation and mixing uniformity. Constructed from high-grade stainless steel and featuring polished internal surfaces, the square cone mixer meets the stringent hygiene requirements of the pharmaceutical and food industries. Its modular design allows for easy customization, with options for various capacities, material contact surfaces, and additional features such as spray systems for liquid addition and vacuum capabilities for sensitive materials.

Comprehensive Maintenance Protocol for Longevity

Proper maintenance is crucial for ensuring the optimal performance and extended service life of Tvtion's square cone mixer. Regular maintenance begins with daily inspections, where operators should check for any unusual noises, vibrations, or leaks before and after operation. The equipment should be thoroughly cleaned after each use, following established sanitation protocols that include disassembly of accessible parts, proper cleaning with approved agents, and complete drying before reassembly. Monthly maintenance involves detailed inspection of the drive system, including motor, gearbox, and bearings, with lubrication performed according to manufacturer specifications. Quarterly comprehensive checks should include verification of alignment, inspection of seals and gaskets, and calibration of control systems. Annual maintenance requires complete disassembly for internal inspection, replacement of worn components, and performance validation to ensure the mixer continues to operate at peak efficiency.

Operational Advantages in Various Industries

The versatility of Tvtion's square cone mixer makes it an indispensable asset across multiple industrial sectors. In pharmaceutical applications, it ensures perfect homogeneity of active pharmaceutical ingredients (APIs) and excipients while maintaining product integrity. Food processing facilities benefit from its gentle mixing action that preserves ingredient characteristics and prevents degradation. Chemical manufacturers appreciate its ability to handle various powder densities and compositions without segregation. The new-energy sector utilizes it for uniform blending of electrode materials, while powder metallurgy operations rely on its precision for creating consistent metal powder mixtures. The equipment's closed system design prevents contamination and protects operators from exposure to hazardous materials, making it suitable for handling toxic or sensitive substances in controlled environments.

Comparative Analysis

Understanding the distinct advantages of square cone technology helps manufacturers make informed decisions about their blending processes:

Aspect | Tvtion Square Cone Mixer | Conventional Blenders |

Mixing Efficiency | Thorough and higher mixing uniformity of blending materials | Often incomplete mixing |

Product Gentleness | Gentle tumbling action preserves particles | May cause particle damage |

Cleaning Accessibility | Easy disassembly and smooth surfaces | Complex cleaning procedures |

Cross-Contamination | Closed system prevents contamination | Open systems risk contamination |

Energy Consumption | Efficient design reduces power usage | Higher energy requirements |

This comparison clearly demonstrates the technological superiority and operational advantages of Tvtion's square cone mixer over traditional blending equipment.

Global Service Support and Quality Assurance

Tvtion's commitment to customer satisfaction extends beyond equipment manufacturing to comprehensive after-sales support. The company provides detailed operational training, maintenance guidance, and technical support to ensure optimal performance of every square cone mixer installed worldwide. Each unit undergoes rigorous testing and quality verification before shipment, guaranteeing reliability and performance consistency. Tvtion's global network of service engineers and technical partners ensures prompt assistance and spare parts availability, minimizing downtime for customers. The company's quality management system, certified to international standards, ensures that every square cone mixer meets the highest requirements of durability, performance, and safety.

Excellence in Powder Processing Solutions

Tvtion's square cone mixer represents the perfect fusion of innovative design, precision engineering, and practical functionality. As industries continue to demand higher quality standards and operational efficiency, this advanced blending solution offers manufacturers a significant competitive advantage. By choosing Tvtion's square cone mixer, companies invest not only in superior equipment but also in a partnership with a global leader dedicated to their success. The machine's proven performance across numerous applications and countries makes it the ideal choice for businesses seeking to enhance their powder processing capabilities while maintaining the highest standards of quality and efficiency.

By Carson Zhao

The Founder of Tvtion Machinery Tech.

With more than 15 years of deep-rooted expertise in powder applications, I am Carson Zhao, the founder of Tvtion Machinery Tech, a company dedicated to delivering innovative and high-efficiency solutions for powder handling, mixing, screening, and processing across industries. My passion lies in solving complex powder-related challenges—whether in pharmaceuticals, food, chemicals, plastic, metal powder, etc. —by leveraging cutting-edge technology and hands-on industry experience.

Let's collaborate to transform your powder processes into a competitive advantage.

EN

EN