Basic Principle of V Blender Mixer

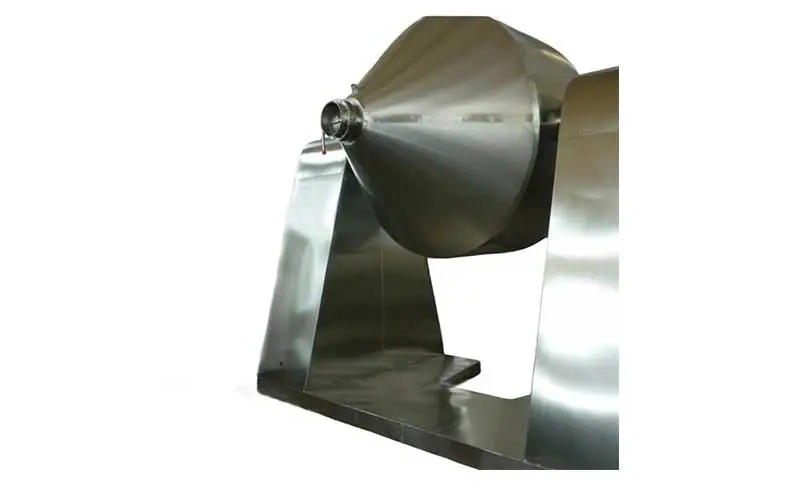

The V blender mixer is a highly efficient mixing device that achieves uniform mixing primarily through the flow and stirring of materials in the V-shaped trough. Its basic working principle is as follows:

Material Filling: Materials enter the V-shaped trough of the V shaped blender through the feed inlet, ready for mixing.

V-shaped Trough Design: The two sides of the V-shaped trough are designed as slopes, with the bottom generally being round or oval. This design helps the materials form a spiral flow within the trough, further promoting the mixing effect.

Rotational Stirring: Inside the V shaped blender, there is a rotating stirrer. Under the action of the stirrer, the materials are pushed towards the trough wall and then, through gravity, return to the center of the trough. This ensures that the materials continuously circulate within the V-shaped trough, ensuring uniform mixing.

Uniform Mixing: During the rotational stirring process, materials undergo shear and impact forces, achieving efficient mixing.

Advantages of V Blender Mixer

Compared to traditional mixing equipment, the V shaped blender has several significant advantages:

Uniform Mixing: The design of the V-shaped trough ensures smoother material flow, greatly improving mixing uniformity.

Fast Mixing Speed: The rotating stirrer quickly pushes materials towards the trough wall, optimizing mixing time and enhancing production efficiency.

Strong Adaptability: The V shaped blender is suitable for mixing various materials, including abrasive materials, materials with good fluidity, and materials with similar characteristics.

Low Shear Mixing: The V shaped blender utilizes a low shear method for mixing, reducing friction heat and fine powder generation, effectively protecting materials from excessive damage.

Application Areas of V blender Mixer

The V blender mixer is widely used in multiple industries, mainly including:

Chemical Industry: Used for mixing pigments, resins, fillers, etc., ensuring the uniform distribution of different components.

Pharmaceutical Industry: In the production process of medicines and health products, the V blender mixer can achieve precise mixing of drugs, ensuring product quality.

Food Industry: Used for mixing food additives, feeds, and other materials to meet different production requirements.

Material Handling: Provides uniform heat distribution, avoids dead spots, and adapts to various batch and temperature conditions, ensuring efficient mixing.

Additionally, in equipment with a heating jacket, the V blender mixer can achieve continuous heat exchange, eliminating mixing dead spots, providing uniform heat distribution, and eliminating the need for remixing.

Maintenance and Care of V Blender Mixer

To ensure the long-term stable operation of the V blender mixer, regular maintenance and care are crucial. Here are some key maintenance recommendations:

Regular Inspection: Periodically check the V-shaped trough, stirrer, and other components of the V blender mixer, especially for wear and tear, to ensure the normal operation of the equipment.

Cleaning and Maintenance: Keep the equipment clean, and periodically perform cleaning and disinfection to prevent material residues from affecting subsequent production.

Lubrication Maintenance: Regularly add lubricating oil to the stirrer and other moving parts to ensure smooth operation and reduce wear.

As a leading V blender mixer manufacturer, TVTION is committed to providing efficient and stable mixing equipment solutions. With years of industry experience, TVTION continuously optimizes design, enhances mixing precision and efficiency, and ensures that customers' production needs are perfectly met. Whether in the chemical, pharmaceutical, or food industry, TVTION's V blender mixers can provide you with reliable mixing results and superior performance.

By Carson Zhao

The Founder of Tvtion Machinery Tech.

With more than 15 years of deep-rooted expertise in powder applications, I am Carson Zhao, the founder of Tvtion Machinery Tech, a company dedicated to delivering innovative and high-efficiency solutions for powder handling, mixing, screening, and processing across industries. My passion lies in solving complex powder-related challenges—whether in pharmaceuticals, food, chemicals, plastic, metal powder, etc. —by leveraging cutting-edge technology and hands-on industry experience.

Let's collaborate to transform your powder processes into a competitive advantage.

EN

EN