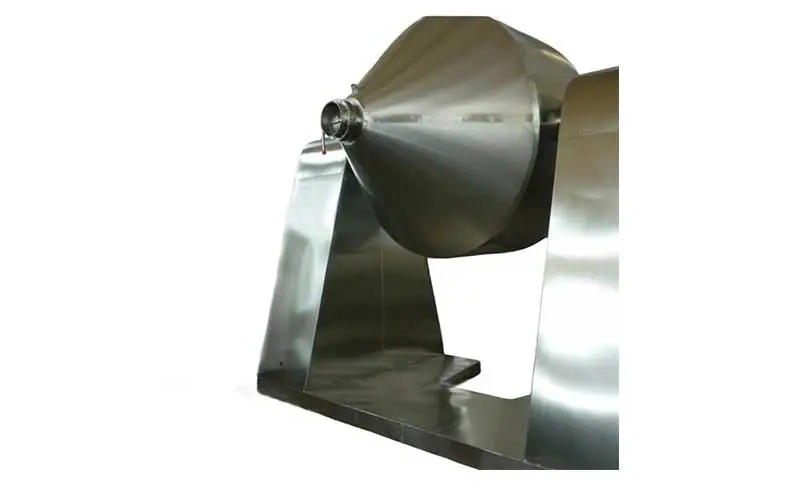

The double cone blender mixer is a highly efficient device widely used for mixing powdered or granular materials. By means of vacuum conveying or manual feeding, the materials are sent into the double cone container, achieving uniform mixing through the rotation of the container. As the container continuously rotates, the materials within it undergo complex impacts and tumbling movements, ultimately reaching a uniform mixing effect. This device not only saves energy, is simple to operate, and has low labor intensity, but it also significantly improves work efficiency. Therefore, it is widely used in industries such as pharmaceuticals, chemicals, food, building materials, etc., for mixing powdery and granular materials.

Working Principle of Double Cone Blender Mixer

The working principle of the double cone blender mixer is based on the principles of centrifugal force and gravity of the materials. When the equipment is running, the motor drives the reducer, which in turn drives the mixing tank to rotate through gear transmission. After the pre-configured powder is added into the mixing tank, as the tank rotates, the materials continuously aggregate and separate under the action of gravity and centrifugal force, ultimately achieving uniform mixing. After the mixing is completed, the materials will be discharged through the discharge port by self-weight. The whole process is simple and efficient.

Components of the Double Cone Blender Mixer

The double cone blender mixer mainly comprises the following parts:

Tank

The tank is made of steel plates and is shaped like a short cylinder set between two cones. The apex angle of the cone is designed according to the repose angle of the mixed materials to ensure uniform mixing. For convenience of discharging, the tank is usually designed at an angle of 90° or 75°. The inlet and outlet ports are equipped with pneumatic or electric butterfly valves, making it easy to control the loading and unloading of materials.

Driving Device

The driving device of the double cone blender mixer consists of a motor, reducer, and transmission gears. The motor speed can be adjusted within a set range to meet different mixing needs. To ensure the accuracy of the mixing process, the driving device is designed with a parking deceleration function, ensuring precise parking of the tank and avoiding excessive rotation. The entire operation process can be managed through an automatic control system.

Slip Ring Cabinet

The slip ring box is an electrical distribution device. All power lines connecting the rotating tank's electrical equipment are input through this box, ensuring the normal power supply of the equipment.

Supporting Frame

The supporting frame is a metal structural frame that supports the tank, driving device, etc., ensuring the stability and safety of the equipment.

With its high efficiency, energy conservation, and simplicity of operation, the double cone blender mixer has become an important device in the mixing operations of various industries. Whether for large-scale production or small-batch trials, the double cone blender mixer can provide reliable performance and excellent mixing results. Choose Tvtion, and you will get higher quality, more stable double cone blender mixer equipment. As a leading equipment manufacturer in the industry, Tvtion is committed to providing innovative, customized solutions for various industries, ensuring that the needs of every customer are precisely met.

By Carson Zhao

The Founder of Tvtion Machinery Tech.

With more than 15 years of deep-rooted expertise in powder applications, I am Carson Zhao, the founder of Tvtion Machinery Tech, a company dedicated to delivering innovative and high-efficiency solutions for powder handling, mixing, screening, and processing across industries. My passion lies in solving complex powder-related challenges—whether in pharmaceuticals, food, chemicals, plastic, metal powder, etc. —by leveraging cutting-edge technology and hands-on industry experience.

Let's collaborate to transform your powder processes into a competitive advantage.

EN

EN