When processing dry materials across industries, achieving consistent particle size distribution and high purity is crucial. The Tvtion powder separator delivers this precision by applying advanced screening and separation mechanisms tailored for modern production demands. Whether handling fine powders in pharmaceuticals or large-volume granules in chemical processing, a powder separator must harmonize design, dynamics and durability to meet rigorous standards.

Powder Separator Technology: Core Design & Functionality

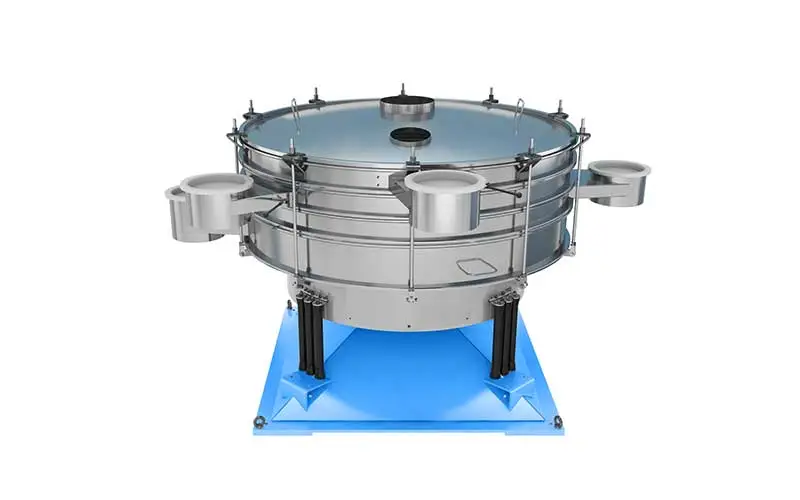

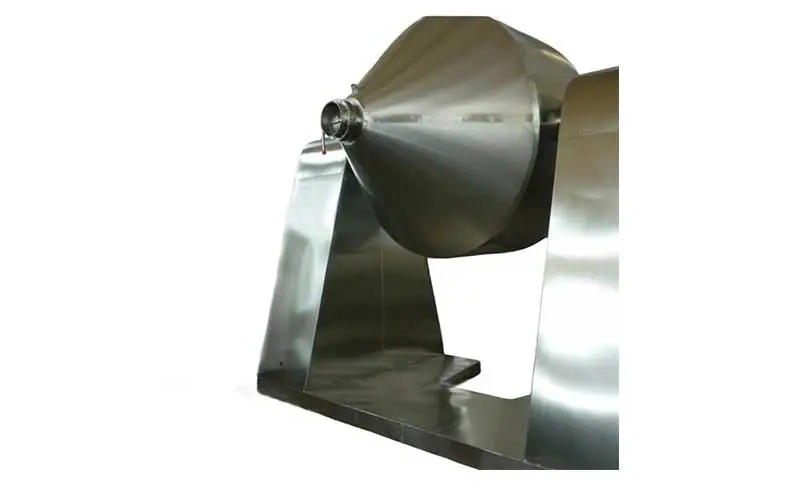

Tvtion's powder separator range includes the Round Separator, Rectangular Gyratory Screen Separator and Powder Conveying System Equipment, each engineered to deliver superior separation performance. The Round Separator uses an ultrasonic sieving frame derived from German technology to prevent mesh clogging, while the sealed structure design controls powder leakage and dust emissions. The Rectangular Gyratory Screen Separator offers a large-capacity screening solution with low noise and high operability, enabling both fine screening to obtain narrow particle size distributions and coarse screening to remove oversized particles. The powder separator is built with precision-machined stainless-steel components and customizable screen decks to handle a wide range of materials, from food-grade powders to metal powders. Altogether, the machinery blends structure and motion to deliver high-efficiency separation, making the concept of a "powder separator" far more than just a screen—it is a dynamic system designed around material characteristics and process objectives.

How Does a Powder Separator Adapt to Different Materials?

The performance of a powder separator depends heavily on the characteristics of the material to be processed. Tvtion's technical literature highlights several key factors: material particle size distribution, moisture content, material properties such as electrostatic behaviour, and mesh aperture of the screen. For example, when the material has a narrow size distribution and large proportion of fine particles, separation precision declines unless the screen aperture and feed conditions are optimized. Similarly, high moisture content causes agglomeration and blocks the mesh, reducing throughput and quality. Tvtion addresses these issues by offering ultrasonic sieving frames for the Round Separator and automatic tension systems for screens, ensuring that even sticky, light or electrostatic powders are handled effectively. The powder separator becomes a versatile tool capable of dealing with coconut powder, rice flour, silica powder, metal powders and more, each with different size, density and flow characteristics. By adapting machine geometry and function to the material, a powder separator achieves separation precision and enhances product value.

What Makes a Powder Separator High-Efficiency?

High efficiency in a powder separator means more than just high throughput—it means achieving consistent quality, minimal downtime, low contamination and effective dust control. Tvtion's powder separator designs incorporate features such as ultrasonic anti-clogging technology in the Round Separator, sealed structures to prevent dust emission, and multi-deck screening in the Gyratory-Screen version for fine grading. The screening motion—whether gyratory or circular—reduces mechanical stress on powders, preserving particle integrity and avoiding degradation. The sealed design and custom conveying systems reduce losses and product contamination, which is especially important in pharmaceuticals and food processing. Through proper screen selection, material loading control and machine configuration, Tvtion ensures the powder separator meets operational and hygiene standards across industries. The term "high-efficiency powder separator" thus embodies a machine that delivers purity, reliability and adaptability, not simply speed.

Powder Separator in Industrial Applications: Typical Use Cases

Industries that require precise separation are among the most demanding, and Tvtion's powder separator is applied widely across food, pharmaceutical, chemical, new-energy, powder metallurgy, plastics, non-metallic materials and feed. For food-grade powders such as coconut or rice flour, the machine must avoid mesh clogging and handle light specific-gravity materials efficiently. For metal powders and battery materials, handling high density, electrostatic effects and a tight particle-size window becomes critical. Tvtion's history of customized solutions—such as a tumbler screen for coconut powder in Vietnam, or a gyratory separator for sand-plastic powder in Russia—illustrates how the right powder separator transforms a production line. In each case, the apparatus is not simply a machine but a tailored system: the powder separator is central to ensuring that the downstream process receives material in the correct size, quality and cleanliness.

Best Practice for Selecting and Maintaining Your Powder Separator

When integrating a powder separator, it pays to view the machine not as a plug-and-play screen, but as a core component of your material-handling process. Begin with a clear profile of the material's particle size distribution, moisture content and other properties such as electrostatics or friability. Match your choice to the correct version—Round, Gyratory. Since the powder separator's efficiency will depend on correct screen aperture, mesh quality and machine configuration, proper installation and commissioning are essential. Regular maintenance is equally important: ensure the screens are tensioned correctly, the ultrasonic or vibration elements functioning, and the sealed pathways remain intact to prevent dust escape. By treating your powder separator as a precision piece of process-equipment rather than a generic machine, you ensure the science behind high-efficiency powder separators becomes reality in your production line.

By Carson Zhao

The Founder of Tvtion Machinery Tech.

With more than 15 years of deep-rooted expertise in powder applications, I am Carson Zhao, the founder of Tvtion Machinery Tech, a company dedicated to delivering innovative and high-efficiency solutions for powder handling, mixing, screening, and processing across industries. My passion lies in solving complex powder-related challenges—whether in pharmaceuticals, food, chemicals, plastic, metal powder, etc. —by leveraging cutting-edge technology and hands-on industry experience.

Let's collaborate to transform your powder processes into a competitive advantage.

EN

EN