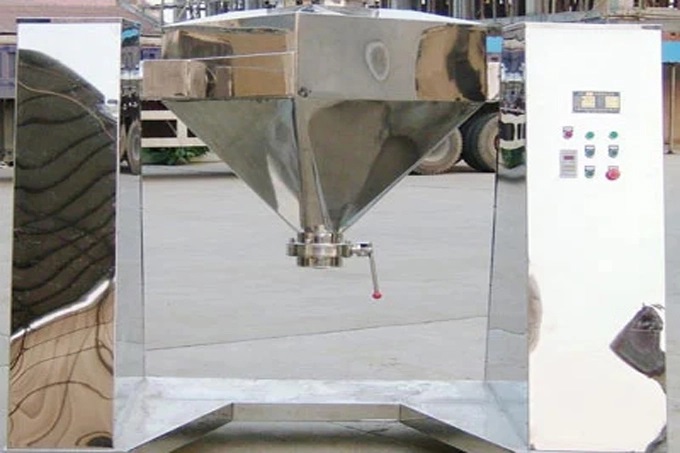

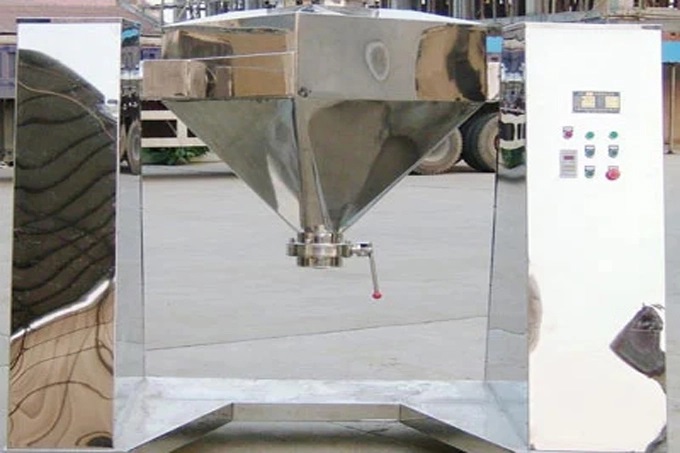

The square cone mixer represents one of the most efficient and reliable solutions for powder blending in modern industrial production. Known for its geometric precision and uniform mixing performance, it plays a crucial role in ensuring material consistency, product quality, and process efficiency. At Tvtion, the design of the square cone mixer emphasizes both mixing homogeneity and operational safety, making it an essential piece of equipment across the pharmaceutical, chemical, and food processing sectors.

Square Cone Mixer Design and Functional Characteristics

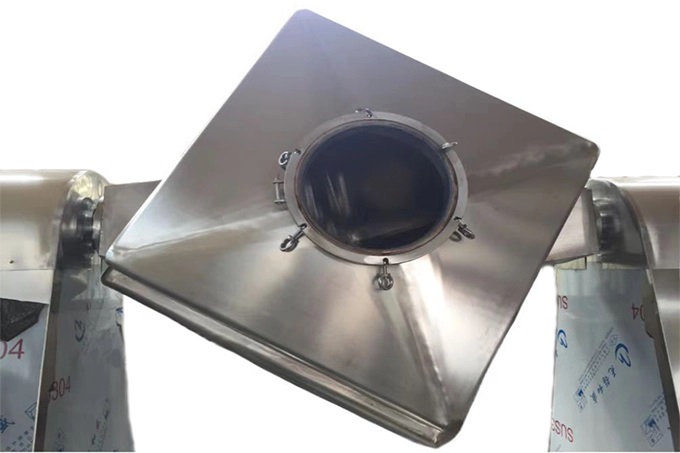

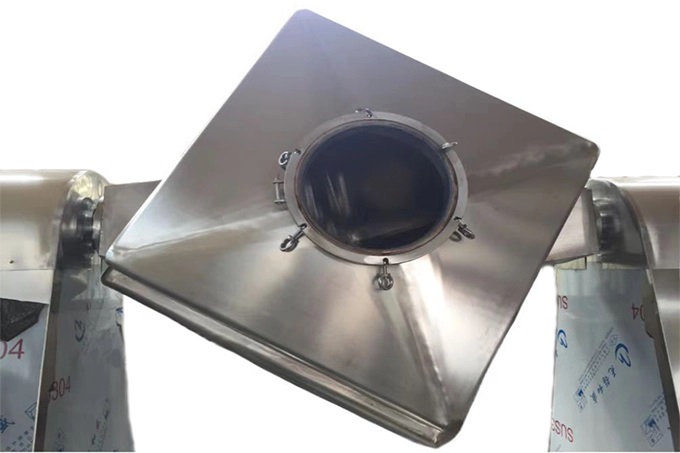

The structure of the square cone mixer combines the principles of three-dimensional motion and gravity blending. The square cone shape allows materials to continuously change positions within the vessel as it rotates, ensuring that every particle participates in the mixing process. This unique design minimizes material accumulation in corners and eliminates segregation caused by particle size or density differences. Built with smooth inner surfaces and high-quality stainless steel, the equipment maintains hygienic standards suitable for pharmaceutical and chemical production environments. The gentle yet thorough blending mechanism also helps preserve the physical integrity of sensitive powders, reducing material loss and maintaining uniform particle size distribution.

Square Cone Mixer in Pharmaceutical Manufacturing

In the pharmaceutical industry, precision and uniformity are paramount, and the square cone mixer is widely adopted for blending active pharmaceutical ingredients (APIs) with excipients. Its controlled rotation speed and symmetrical design ensure that powders mix evenly without generating excess heat or dust, which can alter the chemical stability of delicate compounds. The mixer's fully enclosed structure prevents contamination, meeting strict GMP (Good Manufacturing Practice) standards required in pharmaceutical production. Additionally, its simple disassembly and cleaning features make it ideal for applications that demand cross-contamination prevention and frequent material changes. The consistent blending achieved by the square cone mixer enhances tablet compression quality, capsule filling uniformity, and dosage accuracy, which are vital for maintaining therapeutic effectiveness.

Square Cone Mixer in Chemical Processing

The square cone mixer also finds extensive application in the chemical industry, where uniform distribution of fine powders is essential for product quality and stability. In processes such as pigment mixing, polymer compounding, and catalyst preparation, even the slightest variation in composition can affect the chemical reaction or final product performance. The mixer's square cone geometry enables efficient circulation and blending of both free-flowing and cohesive materials. Its robust construction and variable-speed drive allow for flexible operation, ensuring that different materials—whether fine powders or granular compounds—achieve the required level of homogeneity. This versatility makes it a valuable asset for chemical plants aiming to maintain consistency, improve reaction efficiency, and ensure product reliability.

How Does a Square Cone Mixer Ensure Quality and Efficiency?

The efficiency of a square cone mixer lies in its ability to combine thorough mixing with minimal energy consumption and material residue. The symmetrical rotation mechanism ensures uniform motion of powders along multiple axes, promoting complete blending within a short time frame. Compared with traditional V-type or double-cone mixers, the square cone mixer provides better space utilization and improved mixing uniformity due to its geometric design. The reduction in dead zones inside the vessel ensures that no material remains unmixed, maintaining batch consistency. Its automated control options also allow for precise adjustments to mixing speed and duration, enabling users to optimize processing parameters according to material characteristics. These features contribute not only to high-quality output but also to improved workflow efficiency across industries.

Expanding Applications in Food and Fine Material Industries

Beyond pharmaceuticals and chemicals, the square cone mixer is increasingly used in food and fine material industries where gentle blending and hygiene are critical. It effectively mixes nutritional powders, food additives, spices, and flavoring agents without compromising product texture or aroma. The mixer's stainless steel construction and smooth surfaces facilitate easy cleaning and meet food-grade requirements, while its closed system prevents contamination during operation. In fine material industries such as cosmetics and metallurgy, the mixer ensures even distribution of micro-particles and pigments, supporting stable color and texture in the final products. Its adaptability to various powder characteristics and batch sizes makes it an ideal choice for industries requiring precision and reliability in powder handling and blending.

The square cone mixer continues to evolve as a key technology in material processing, delivering consistency, efficiency, and cleanliness in demanding production environments. By integrating advanced engineering and a user-centered design, Tvtion's square cone mixer supports industries where precision powder blending directly impacts product quality and performance.

By Carson Zhao

The Founder of Tvtion Machinery Tech.

With more than 15 years of deep-rooted expertise in powder applications, I am Carson Zhao, the founder of Tvtion Machinery Tech, a company dedicated to delivering innovative and high-efficiency solutions for powder handling, mixing, screening, and processing across industries. My passion lies in solving complex powder-related challenges—whether in pharmaceuticals, food, chemicals, plastic, metal powder, etc. —by leveraging cutting-edge technology and hands-on industry experience.

Let's collaborate to transform your powder processes into a competitive advantage.

EN

EN