Introudction

In the screening process of solid particle materials, selecting appropriate screening equipment is crucial for improving production efficiency and product quality. Common screening machines include the vibratory sifter and the rectangular gyratory sifter. Each has its unique working method and applicable scope. This article will systematically explain their working principles, performance characteristics, and application fields.

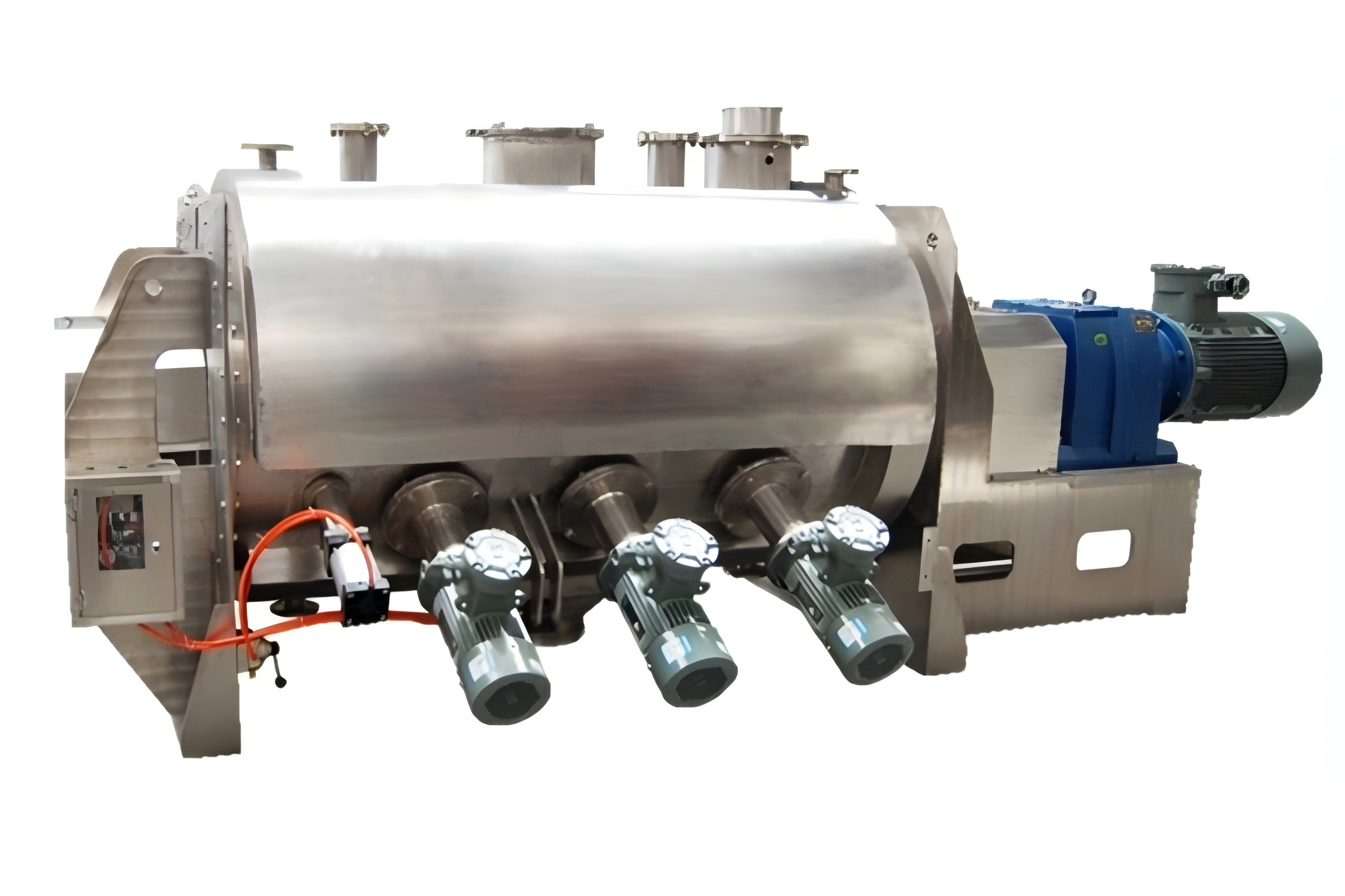

Vibratory Sifter: A Representative of High-Frequency Screening

The vibratory sifter is a screening device that uses a motor vibrator to generate high-frequency vibration. Its principle is to drive the screen mesh to jump up and down through high-speed vertical vibration, thereby promoting the rapid passage of materials through the screen to complete particle size classification.

Main features

Fast screening speed, suitable for continuous production;

Compact structure, easy to clean and maintain;

Applicable to various materials such as dry powder, granules, and liquids;

Commonly used in industries such as food, pharmaceuticals, and chemicals that require high throughput.

Limitations

Not gentle enough for fragile materials or products requiring fine classification, and has relatively low screening accuracy.

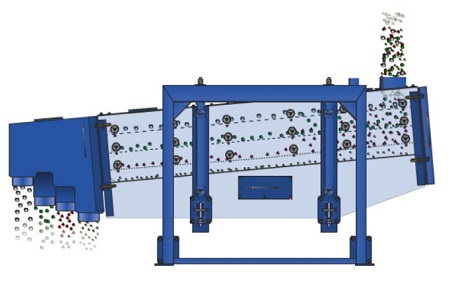

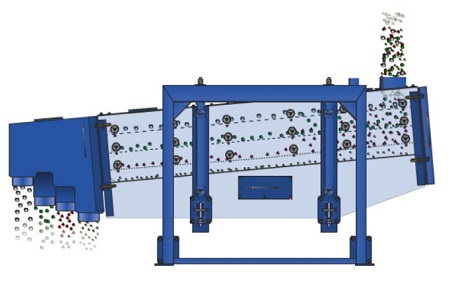

Rectangular Gyratory Sifter: Balancing High Throughput and Precision

The rectangular gyratory sifter is an upgraded version of the gyratory sifter, adopting a rectangular screen surface design and combining the motion principle of the gyratory sifter to achieve efficient screening under high throughput.

Main features

Large screening area, processing capacity far exceeds that of the ordinary gyratory sifter;

High precision, suitable for multi-stage screening;

Stable motion trajectory, uniform material distribution;

Applicable to industries such as minerals, grains, fertilizers, and metallurgy that require both capacity and screening precision.

Limitations

Requires large installation space and has relatively high initial investment costs.

Conclusion

In modern screening processes, the vibratory sifter is suitable for high-speed coarse screening, while the rectangular gyratory sifter balances high output and precise classification. Selecting the right model based on material characteristics, production needs, and plant conditions will greatly enhance production efficiency and product quality. It is an essential step toward intelligent and refined manufacturing.

By Carson Zhao

The Founder of Tvtion Machinery Tech.

With more than 15 years of deep-rooted expertise in powder applications, I am Carson Zhao, the founder of Tvtion Machinery Tech, a company dedicated to delivering innovative and high-efficiency solutions for powder handling, mixing, screening, and processing across industries. My passion lies in solving complex powder-related challenges—whether in pharmaceuticals, food, chemicals, plastic, metal powder, etc. —by leveraging cutting-edge technology and hands-on industry experience.

Let's collaborate to transform your powder processes into a competitive advantage.

EN

EN