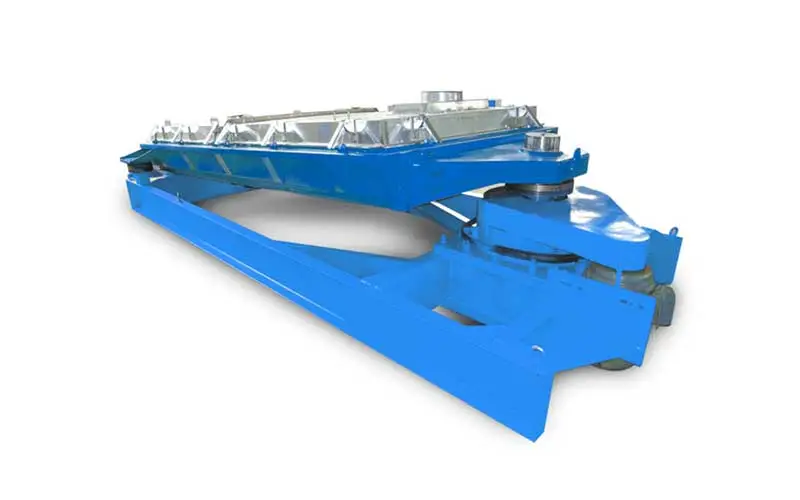

The horizontal ribbon mixer is a high-efficiency device widely used for mixing powder and viscous materials. It consists of a U-shaped cylinder, ribbon stirring blades, and transmission components, featuring a unique structure and strong mixing capability. The ribbon blades are usually designed in double layers; during operation, the outer ribbon gathers the material from both sides to the center, while the inner ribbon transports the material from the center to the sides, forming a convective mixing, thus ensuring uniform mixing of materials in a short time. The design of the stirring parts can also be adjusted according to the characteristics of different materials, using paddle blades or adding choppers to further enhance the mixing effect. The drum lid design can be either arched, which can withstand pressure, or fully open, which facilitates cleaning the interior of the equipment.

Features of the Horizontal Ribbon Mixer

Unique Structure Design

The mixing shaft of the horizontal ribbon blender has inner and outer layers of ribbons. The outer ribbon gathers the material from both sides to the center, while the inner ribbon transports the material from the center to the sides, forming an efficient convective mix. This design ensures stable operation, reliable quality, low noise, and a long lifespan.

Liquid Spray Mixing Function

If there is a need for a liquid spray mixing process, the horizontal ribbon mixer can be equipped with a spray device to produce misty sprays, which helps improve the uniformity of the mix, especially suitable for mixing with liquid additions.

Flexible Adaptation to Different Processes

This equipment can meet conventional mixing processes and can adapt to complex temperature control conditions when heating or cooling is required. Whether it is solid-solid (powder to powder) or solid-liquid (powder to liquid) mixing, the horizontal ribbon mixer can provide efficient solutions.

Efficient Mixing

The horizontal ribbon mixer has a relatively fast mixing speed and high mixing uniformity, able to meet the mixing needs of various materials, especially suitable for materials with high viscosity or large specific gravity that are difficult to mix.

Wide Range of Applications

In addition to powder mixing, the horizontal ribbon blender can also handle paste-like materials with a certain viscosity, making it widely applicable.

Working Principle of the Horizontal Ribbon Mixer

The working principle of the horizontal ribbon mixer is driven by a motor through a reducer, rotating the specially arranged ribbon main shaft. During operation, the outer ribbon gathers the material from both sides to the central position, while the inner ribbon pushes the material from the center to the sides or end panels. The cooperative action of both causes the materials to diffuse, convect, shear, dislocate, and radiate within the cylinder, thus achieving uniform mixing of the materials in an extremely short time.

With its efficient mixing capability, flexible process adaptability, and reliable structural design, the horizontal ribbon mixer has become an indispensable device in many industries. Whether it is powder mixing or handling viscous materials, the horizontal ribbon mixer can provide excellent mixing results, meeting various complex process requirements. Choosing a high-quality horizontal ribbon mixer will provide more efficient and reliable solutions for your production process. Tvtion is dedicated to providing high-performance mixing equipment and customized solutions based on customer needs. As an industry-leading equipment manufacturer, Tvtion will bring higher efficiency, more stable performance, and superior service to your production.

By Carson Zhao

The Founder of Tvtion Machinery Tech.

With more than 15 years of deep-rooted expertise in powder applications, I am Carson Zhao, the founder of Tvtion Machinery Tech, a company dedicated to delivering innovative and high-efficiency solutions for powder handling, mixing, screening, and processing across industries. My passion lies in solving complex powder-related challenges—whether in pharmaceuticals, food, chemicals, plastic, metal powder, etc. —by leveraging cutting-edge technology and hands-on industry experience.

Let's collaborate to transform your powder processes into a competitive advantage.

EN

EN