Technology and Features of the Powder Separator

The powder separator is a device that uses aerodynamic principles to classify and separate powder materials. Its main working method is to send powders of different particle sizes into the separation chamber through airflow, and rely on centrifugal force, inertial force, and other effects to effectively separate coarse and fine particles. The powder separator is usually equipped with a cyclone separation mechanism, which enables precise particle size screening in high-speed airflow.

Technical advantages of the powder separator include:

Efficient classification: By adjusting airflow speed and the angle of the cyclone separator, it can achieve precise separation within a very narrow particle size range;

Screenless design: Avoids the problem of screen clogging, has low maintenance cost, and is suitable for materials with high moisture content or prone to agglomeration;

Strong continuous operation capability: Suitable for large-scale industrial production, maintaining long-term stable operation;

Diverse applicability: Widely used in powder processing in industries such as chemicals, pharmaceuticals, mining, and building materials.

Technical Features of the Gyratory Separator

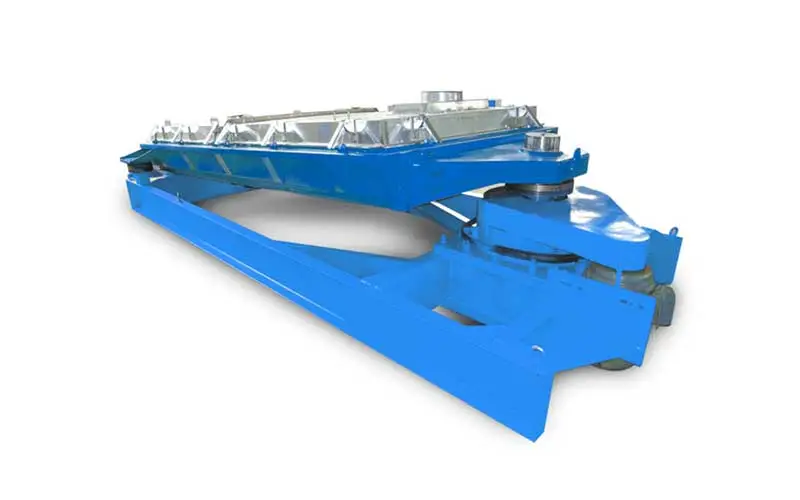

The gyratory separator, also known as the gyratory screen, is a device that achieves material separation through mechanical gyratory motion. Its screen surface makes a circular motion along the horizontal plane, and the material performs rotation, jumping, and layering on the screen surface, promoting the separation of particles of different sizes along different paths. The gyratory separator is especially suitable for high-precision screening of powders and granules.

Notable features of the gyratory separator include:

High screening accuracy: The mechanical gyratory motion increases the separation efficiency of materials, suitable for applications with strict particle size distribution requirements;

High screen surface utilization: Material is evenly distributed, reducing blind spots and screen clogging;

Low vibration and noise: Smooth operation, suitable for production workshops with high environmental requirements;

Multi-layer screening design: Can achieve multi-stage classification and improve screening efficiency.

Comparison of Applicable Materials and Performance

The powder separator is suitable for processing powders with a wide particle size distribution, high moisture content, prone to agglomeration or difficult to screen, and performs especially well in industries such as chemicals, pharmaceuticals, and mining. Due to its screenless design, it is easy to maintain and has strong continuous operation capability.

The gyratory separator is suitable for powders and granules that have good flowability, are dry, and have strict particle size requirements, such as food powders, fine chemical raw materials, and pharmaceutical granules. Its high screening accuracy and low vibration noise make it suitable for production environments with high environmental standards.

Application Selection Recommendations

If the material has complex characteristics, high moisture content, and requires large-scale continuous classification, it is recommended to choose the powder separator. Its airflow separation effect is remarkable, and maintenance costs are relatively low.

If the product has strict requirements on particle size distribution, high screening accuracy, and the material has good flowability, it is recommended to use the gyratory separator. Its mechanical screening method better ensures the quality of the final product.

By Carson Zhao

The Founder of Tvtion Machinery Tech.

With more than 15 years of deep-rooted expertise in powder applications, I am Carson Zhao, the founder of Tvtion Machinery Tech, a company dedicated to delivering innovative and high-efficiency solutions for powder handling, mixing, screening, and processing across industries. My passion lies in solving complex powder-related challenges—whether in pharmaceuticals, food, chemicals, plastic, metal powder, etc. —by leveraging cutting-edge technology and hands-on industry experience.

Let's collaborate to transform your powder processes into a competitive advantage.

EN

EN